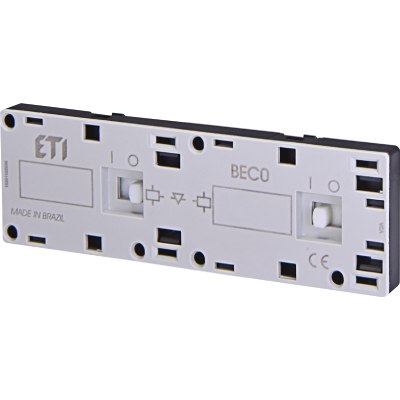

Advanced Assembly Equipment Improves Efficiency and Quality in FI Relay Production

Advanced Assembly Equipment Improves Efficiency and Quality in FI Relay Production

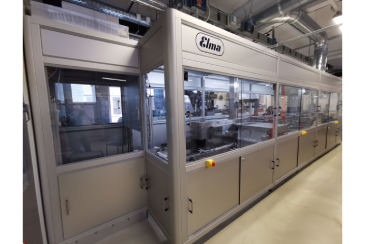

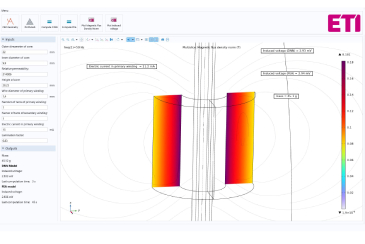

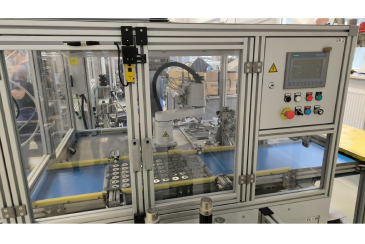

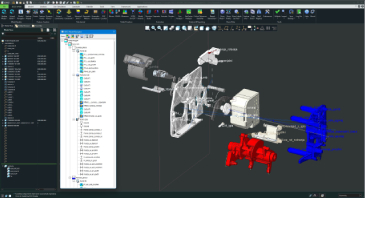

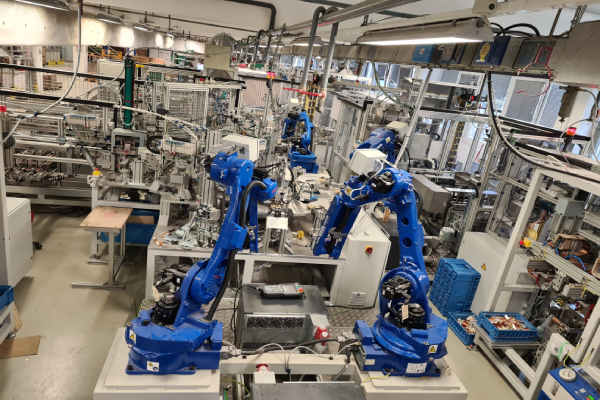

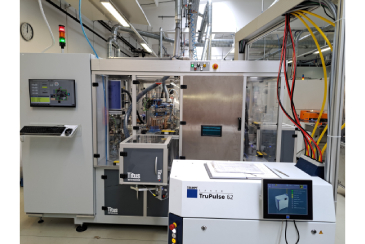

At ETI, we're continuously driving innovation to enhance the precision, efficiency, and reliability of our production processes. One of our most recent achievements in this journey is the new assembly and welding machine for magnetic systems used in FI relays—a solution that brings us closer to a smarter, more controlled manufacturing future. This project has also been awarded a national award for innovation from Chamber of Commerce and Industry of Slovenia.

| Jakob Jesenšek |