Future-Proofing ETI Elektroelement Through Simulation: The Power of Surrogate Models

In today’s fast-paced world, innovation in production processes is key to staying competitive, especially in industries like electrical equipment manufacturing. ETI Elektroelement d.o.o., a leading provider of electrical installations and power electronics, has made significant strides in embracing advanced simulation technologies to streamline their design processes. By integrating surrogate models into their COMSOL Multiphysics simulations, ETI has opened new doors for faster iterations and optimization of their residual current devices (RCDs). This bold move exemplifies how production innovation can lead to significant improvements in product quality, development speed, and cost efficiency.

| Lucjan Strehar |

Meeting Industry Challenges Through Innovation

The electrical equipment industry is incredibly competitive, with companies constantly seeking ways to deliver top-quality products at competitive prices. For ETI Elektroelement, the challenge extends beyond cost—it's about maintaining rapid adaptability and a high standard of product quality while managing tight project timelines. At the heart of their innovation efforts is the design of their residual current devices (RCDs), which are vital for protecting users from electrical shock by breaking faulty electrical circuits quickly and reliably.

One of the most critical components of an RCD is the differential transformer core, which detects differences in the current flow and triggers circuit disconnection when necessary. The challenge for ETI is to optimize the design of this core—both in terms of performance and cost—while avoiding delays that could result from inaccurate prototypes or suboptimal designs. This is where simulation technology, specifically COMSOL Multiphysics, has played a crucial role.

The Power of Surrogate Models in Production Innovation

The Power of Surrogate Models in Production Innovation

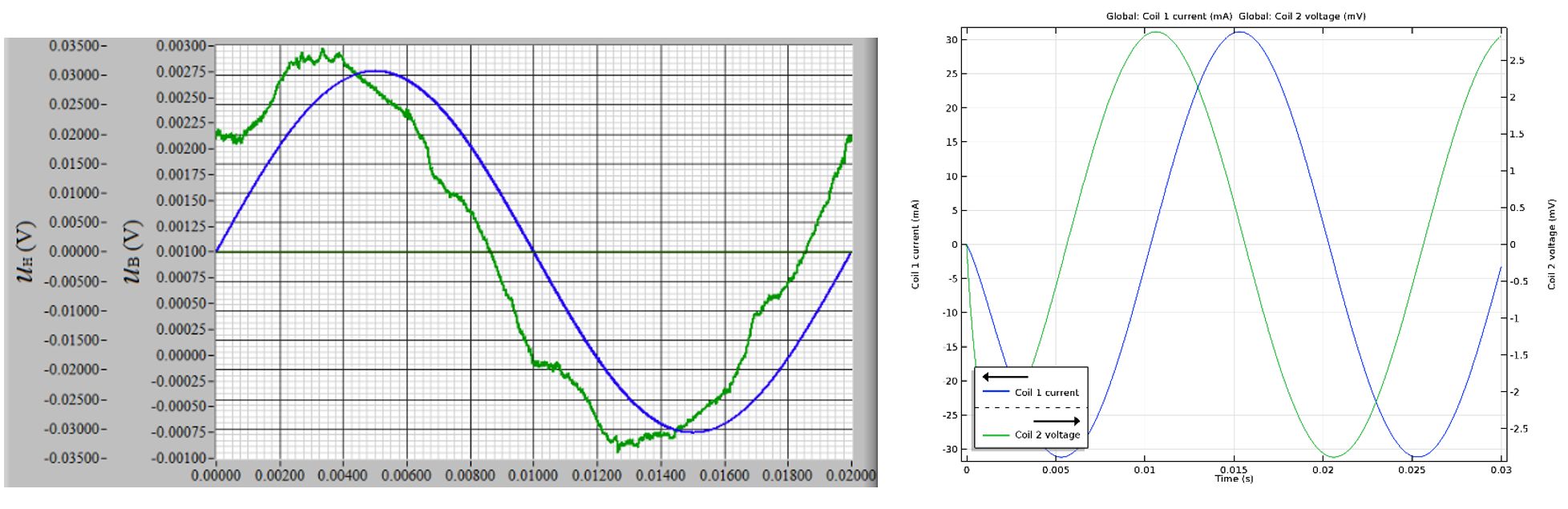

To overcome these challenges, ETI Elektroelement developed a simulation model using COMSOL Multiphysics. The model simulates the magnetic fields, current flows, and core behavior, allowing engineers to optimize the geometry and material properties of the transformer core. But what truly sets ETI apart in their innovation journey is the integration of surrogate models into this simulation process.

Surrogate models, built from a comprehensive dataset generated through a design of experiments (DOE) approach, are capable of predicting system behavior under various conditions without running full-scale simulations every time. This enhancement drastically reduces the time required for simulations, which in turn speeds up the overall design process.

The benefits of this innovative approach are clear: engineers at ETI can now perform complex analyses and simulations without being experts in finite element analysis (FEA). This democratization of simulation technology has allowed more team members to contribute to the design and optimization of RCDs, leading to quicker iterations, faster decision-making, and ultimately, improved product quality.

Impact on Production and Quality Control

One of the most impressive outcomes of ETI's innovation efforts is the ability to predict deviations in core parameters with unprecedented accuracy. The surrogate model allows engineers to adjust core geometry, magnetic properties, and other critical parameters in real time. By understanding how small changes affect the overall performance of the core, ETI has been able to minimize errors in production, reduce the risk of defects, and maintain strict adherence to quality standards.

In addition, the streamlined simulation application can be easily distributed across ETI’s organization. This has fostered collaboration and allowed different teams to contribute to product innovation, enhancing overall productivity and innovation efforts within the company.

A Blueprint for Future Innovation

ETI Elektroelement’s integration of surrogate models into their COMSOL Multiphysics simulations serves as a powerful example of how production innovation can revolutionize traditional industries. By empowering more engineers to participate in complex simulations, ETI has unlocked new opportunities for faster, more efficient product development.

The ability to quickly iterate, optimize designs, and predict the impact of manufacturing deviations has not only reduced development time but also contributed to higher product quality. In an industry where delays and defects can be costly, this approach has given ETI a significant competitive edge.

As the electrical equipment industry continues to evolve, ETI’s success in leveraging surrogate models points toward a future where production innovation and digital technologies are the driving forces behind smarter, more efficient manufacturing processes.

Conclusion

ETI Elektroelement d.o.o. has successfully turned simulation-driven innovation into a strategic advantage in the design and manufacturing of circuit breakers. By integrating surrogate models into their COMSOL Multiphysics simulations, they’ve drastically reduced the time required for design iterations, improved accuracy in production, and fostered a more collaborative work environment. This approach underscores the importance of embracing cutting-edge technologies in production processes to stay competitive in today’s market.

For companies looking to innovate their production processes, ETI’s experience shows that investing in advanced simulation technologies can lead to faster product development, higher quality standards, and ultimately, greater success in an increasingly competitive industry.