New developments in overcurrent protection of PV inverters

Recent changes in the field of PV (Photo-Voltaic), mainly related to the expected voltage levels on both the input (DC) direct current of inverters (DC / AC converter) and the output, AC - alternating current, have also had an impact on overcurrent protection of these inverters.

| Viktor Martinčič Product manager |

These changes mainly pertain to system voltage. For example, while in 2018, 1000 and 1100V d.c. systems were predominantly used in PV installations, all recent trends indicate that PV systems with 1500V d.c. voltage will prevail in 2021.

Central and String Inverters:

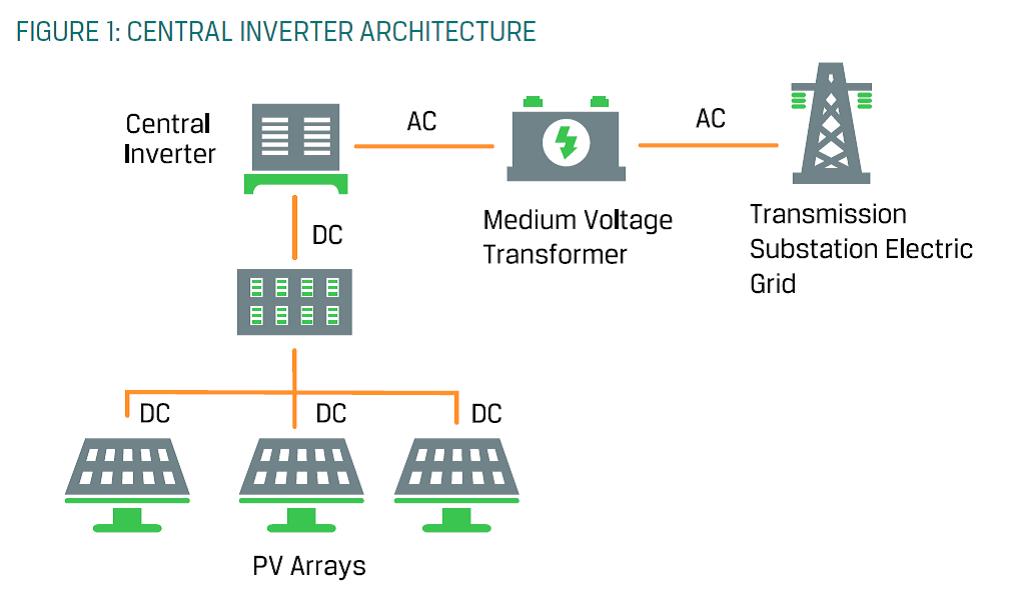

Many changes are also occurring in the configurations of PV systems, where central inverters are being replaced by string inverters. Each of the two mentioned groups has its own advantages and PV system designers have to consider what the advantages of the selected inverter will bring about greater efficiency of the entire PV system.

Configuration with a central inverter in a PV installation system:

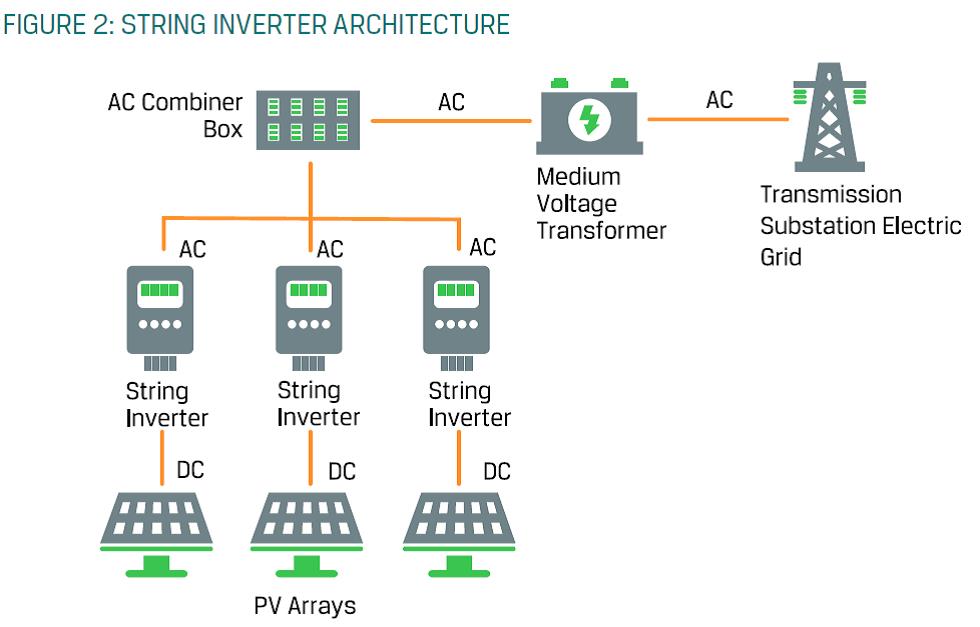

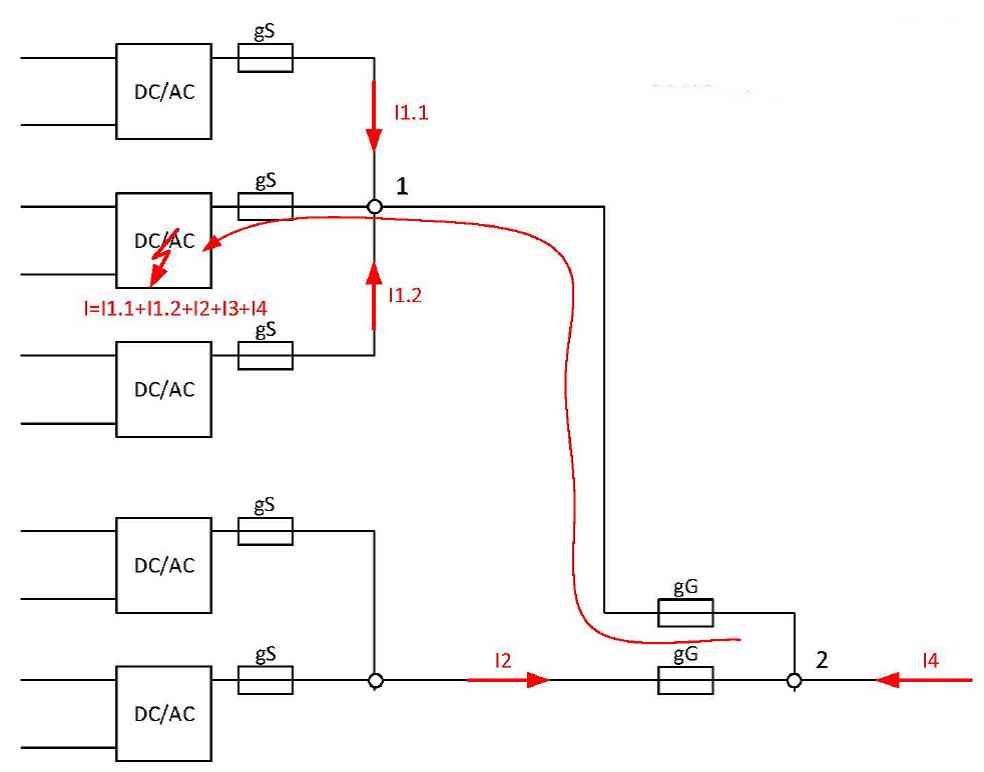

New versions of inverters, also called string inverters, are being developed by all major manufacturers in the world, most notably ABB, HUAWEI and SMA. An example of including this type of inverter in the PV system:

The "string" group of PV inverters is connected to a common circuit called the AC combiner box (basically an AC collector unit) by means of a.c outputs. Therefore, DC / AC converters are getting more and more advanced, their features are getting better, they have become smart, safe, reliable and efficient electronic devices.

And where does ETI appear in this story?

Where else than providing adequate overcurrent protection for these PV systems….

Of course, it makes perfect sense that all PV system designers and manufacturers of photovoltaic equipment are looking for different ways to improve their efficiency and ultimately their financial return.

Higher yields are achieved by using dynamic optimization of system performance with intelligent technology. Currently, their achieved efficiency exceeds 98.5%. One of the most important technical features of the new generation of "string" inverters, however, is the higher output AC voltage, which, instead of the current 400V a.c. now elevated to 800V a.c.

By increasing the output voltage, manufacturers have achieved up to 75% reduction in power dissipation in cables that connect the output of the "inverter" string to the input of the power distribution medium voltage transformer. In addition, smaller cross-section cables can of course be used, which also means cost savings.

However, due to the higher output a.c. voltage, modern "string" inverters also require adequate overcurrent protection, ie a fuse capable of operating properly at voltages higher than the standard 500V or 690V a.c.

As one of the first manufacturers, ETI has developed a new generation of NH gG fuse links to protect cables in 800V a.c. installations. With the innovative design and other components, we are able to offer a wide range of NH gG fuse-links tested at 800V a.c. which are dimensionally identical to the standard NH gG 500V / 690V series, so they do not have to be used with fuse bases or fuse disconnectors of different non-standard dimensions.

Currently, we offer NH gG 800V a.c. fuse links sizes 00, 1 in 3 with rated currents from 25A to 315A. We have also developed a series of NH fuse links with gS current-time characteristic, which enables faster disconnections at specified current times than the gG characteristic. It should also be noted that a proposal for addition of these fuses to basic fuses standard IEC 60269-1 is already being prepared by IEC SC32B commitee, thus ensuring that proper protection of inverters with rated voltage of 800V a.c. will be standardized.

Examples of NH fuse-links in this series:

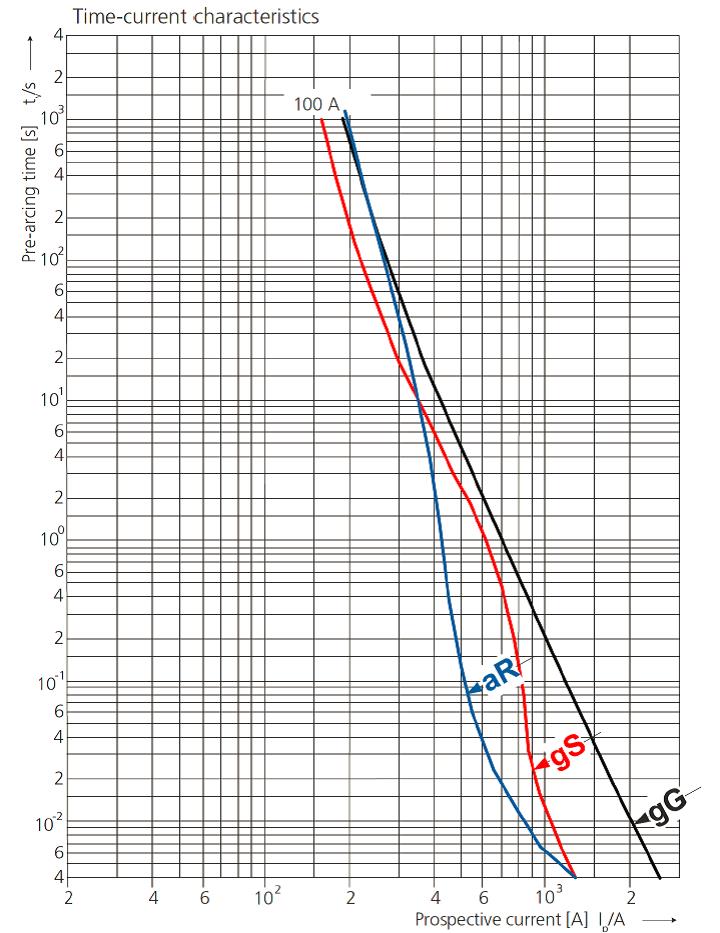

The figure below shows a comparison of the three most recognizable current-time characteristics of the fuse links, all of which are sized to rated current 100A. A feature called gG (G = General) is by far the most widely known and used in everyday practice of overcurrent and short circuit protection of residential and industrial electrical installations. The primary task of gG-type fuse-links is to protect cable installations against overloads and the effects of short-circuit currents.

Another, very familiar current-time characteristic is one that was developed to protect power semiconductors, called gR / aR (R = Rectifier).

From the graph below, it can be seen that a fuse link with an aR characteristic at a current of, for example, 500A will burn out in a time of about 100ms, while one with a characteristic of gG at the same overcurrent will take about 4 seconds. This makes a considerable difference…

In practice, another current-time characteristic called gS is becoming very popular and commonly used. It was incorporated into the IEC 60269-4 standard a few years ago, as modern applications required a fuse link, which is much faster than gG in the operating range between 10ms and 100ms - but at the same time, much slower than gR. This characteristic is also characterized by much lower power losses and reduced overheating.

Example:

For (normally) short-circuit current in the 900A circuit, a fuse-link with gS characteristic will disconnect in 20ms, while at the same over current, a fuse link with gG characteristic will take 300ms to disconnect. That's a pretty big difference...

An example of the use of fuse-links with both of the current-time characteristics described above:

| Features and benefits: | |

| - Load switching capacity up to 800V a.c. - Meets IEC photovoltaic standards - In standard NH size dimensions - Extremely low power dissipation - High breaking capacity - Designed to protect against a full range of overcurrents - High temperature and internal pressure resistant ceramic material - Innovative design of melting elements |  |